From Gears to Idlers: The Total Option for Trustworthy Undercarriage Parts

Wiki Article

Make The Most Of Efficiency With Long Lasting Undercarriage Parts

In the world of hefty equipment and equipment, the duty of undercarriage parts is vital in making sure optimal performance and longevity. The efficiency and performance of these components can considerably affect the general procedure of machinery, making the option of resilient undercarriage components an essential decision for operators and supervisors alike. By exploring the intricate partnership between longevity and performance in undercarriage parts, a deeper understanding of the subject arises, clarifying the essential factors that drive operational success. As we browse through the intricacies of undercarriage longevity, maintenance, and part choice, an extensive exploration awaits to reveal the vital strategies for accomplishing peak efficiency in sturdy applications.Benefits of Using Durable Undercarriage Components

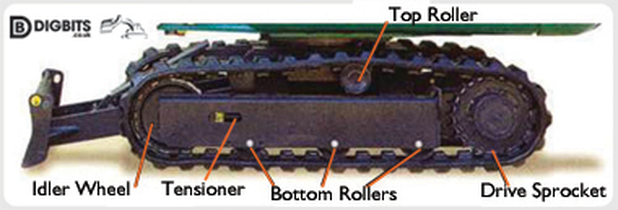

Making use of sturdy undercarriage components not just boosts the long life of hefty equipment but likewise reduces upkeep expenses dramatically. By buying high-grade undercarriage parts, such as tracks, rollers, sprockets, and idlers, tools drivers can experience enhanced uptime and enhanced general performance.

Furthermore, the durability of hefty machinery is directly linked to the high quality of its undercarriage components. Resilient parts can withstand the rigors of demanding applications, making certain that the equipment stays functional for extended periods. As an outcome, drivers can avoid expensive downtime and upkeep expenses, eventually making best use of the roi for their equipment.

Variables Impacting Undercarriage Toughness

The durability of undercarriage parts in heavy equipment is influenced by various vital aspects that straight influence efficiency and longevity. Among the essential elements affecting undercarriage sturdiness is the high quality of products utilized in manufacturing. Premium materials, such as solidified steel, are crucial for enduring the extreme conditions and heavy tons that undercarriage parts are subjected to. Proper maintenance techniques also play an essential role in identifying the lifespan of undercarriage parts. Routine evaluations, lubrication, and timely substitute of damaged parts can significantly expand the toughness of the undercarriage.Moreover, ecological aspects can have a considerable influence on the long life of undercarriage parts. Direct exposure to abrasive products, extreme temperature levels, and rough working conditions can increase deterioration on undercarriage parts. Choosing undercarriage components that are especially developed to hold up against these environmental difficulties is vital for guaranteeing longevity.

Additionally, the style and design of undercarriage components look at more info have a straight impact on their resilience. Parts that are created to disperse tons equally, reduce friction, and minimize tension concentrations are most likely to have a longer life expectancy - undercarriage parts. By thinking about these essential variables, tools drivers can maximize the resilience and performance of their undercarriage components

Maintenance Tips for Lengthening Undercarriage Life

Implementing normal upkeep routines is important for extending the life-span of undercarriage elements in heavy equipment. In addition, guarantee that the undercarriage is correctly oiled according to maker guidelines to minimize friction and protect against premature wear.Another vital upkeep suggestion is to maintain the undercarriage clean from dust, rocks, and particles. Buildup in the undercarriage can increase wear and rust, leading to costly repair services. Washing the undercarriage after operation in extreme problems is recommended to stop these problems.

Last but not least, tracking and recording upkeep activities can assist in developing a positive upkeep routine. Maintaining comprehensive records of replacements, repair services, and inspections can offer beneficial understandings into the undercarriage's problem and efficiency with time, aiding in anticipating and stopping possible failures. By following these maintenance ideas faithfully, operators can dramatically raise the sturdiness and efficiency of undercarriage components in heavy machinery.

Choosing the Right Undercarriage Parts

Selecting appropriate undercarriage elements is important for making the most of the efficiency and view it now durability of hefty machinery. When it comes to choosing the ideal undercarriage components, there are numerous aspects to consider.In addition, thinking about the top quality and track record of the manufacturer is crucial. Going with reliable brand names known for creating durable and high-performance undercarriage components can considerably influence the general performance and longevity of the equipment. Ensuring that the elements are suitable with the equipment model and properly set up is critical for optimal performance. By very carefully picking the right undercarriage elements, devices proprietors can improve performance, lower downtime, and extend the life expectancy of their hefty equipment.

Study: Boosted Efficiency With Resilient Parts

Incorporating long lasting undercarriage parts has actually demonstrated substantial enhancements in equipment efficiency. One case research entailed a building firm that upgraded its excavator's undercarriage parts to a lot more durable choices. The company observed a remarkable decrease in downtime as a result of undercarriage upkeep, resulting in raised productivity and price savings. The long lasting parts stood up to harsh working conditions, minimizing wear and tear dramatically.In one more circumstances, a mining procedure replaced the undercarriage parts of its bulldozer with high-grade, durable options. This button caused a remarkable improvement in the bulldozer's maneuverability and general efficiency. The equipment could navigate difficult click this site surfaces extra successfully, resulting in improved operational effectiveness and lowered fuel consumption.

Furthermore, a logging business invested in sturdy undercarriage components for its forestry devices. These situation studies underscore the substantial benefits of using durable undercarriage components in enhancing machinery performance and long life.

Final Thought

In verdict, utilizing long lasting undercarriage parts can substantially boost performance and durability of hefty machinery. Situation researches have revealed that investing in resilient undercarriage components can lead to improved overall efficiency and performance in various markets.The performance and effectiveness of these components can substantially affect the total operation of machinery, making the choice of sturdy undercarriage parts a vital choice for drivers and supervisors alike.Incorporating resilient undercarriage parts has shown substantial improvements in equipment efficiency. These instance researches underscore the tangible benefits of utilizing long lasting undercarriage components in maximizing equipment efficiency and long life.

In conclusion, utilizing resilient undercarriage parts can substantially boost efficiency and durability of hefty equipment (undercarriage parts). Instance researches have actually revealed that spending in long lasting undercarriage components can lead to boosted total efficiency and efficiency in different industries

Report this wiki page